Patented technology

for protective components

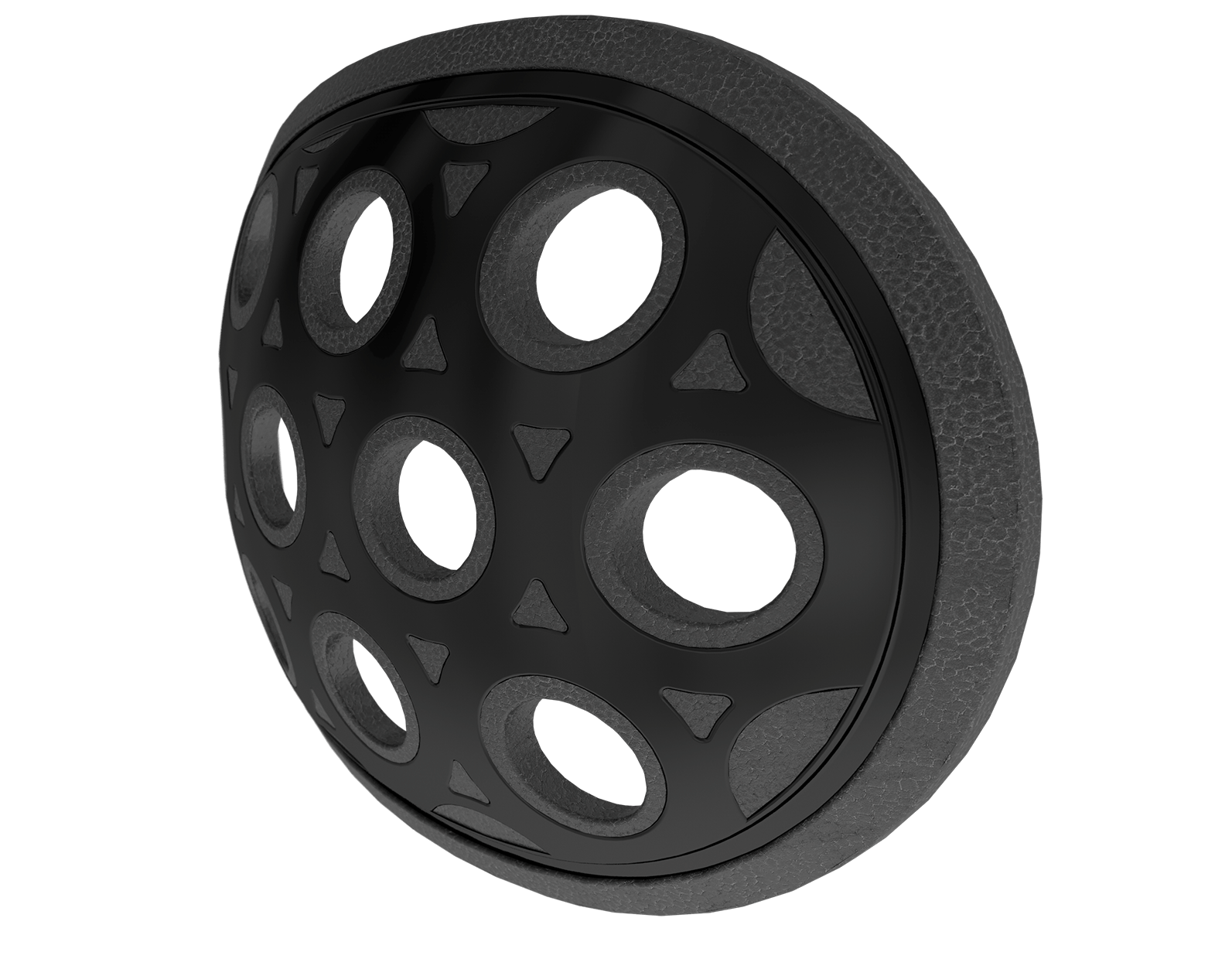

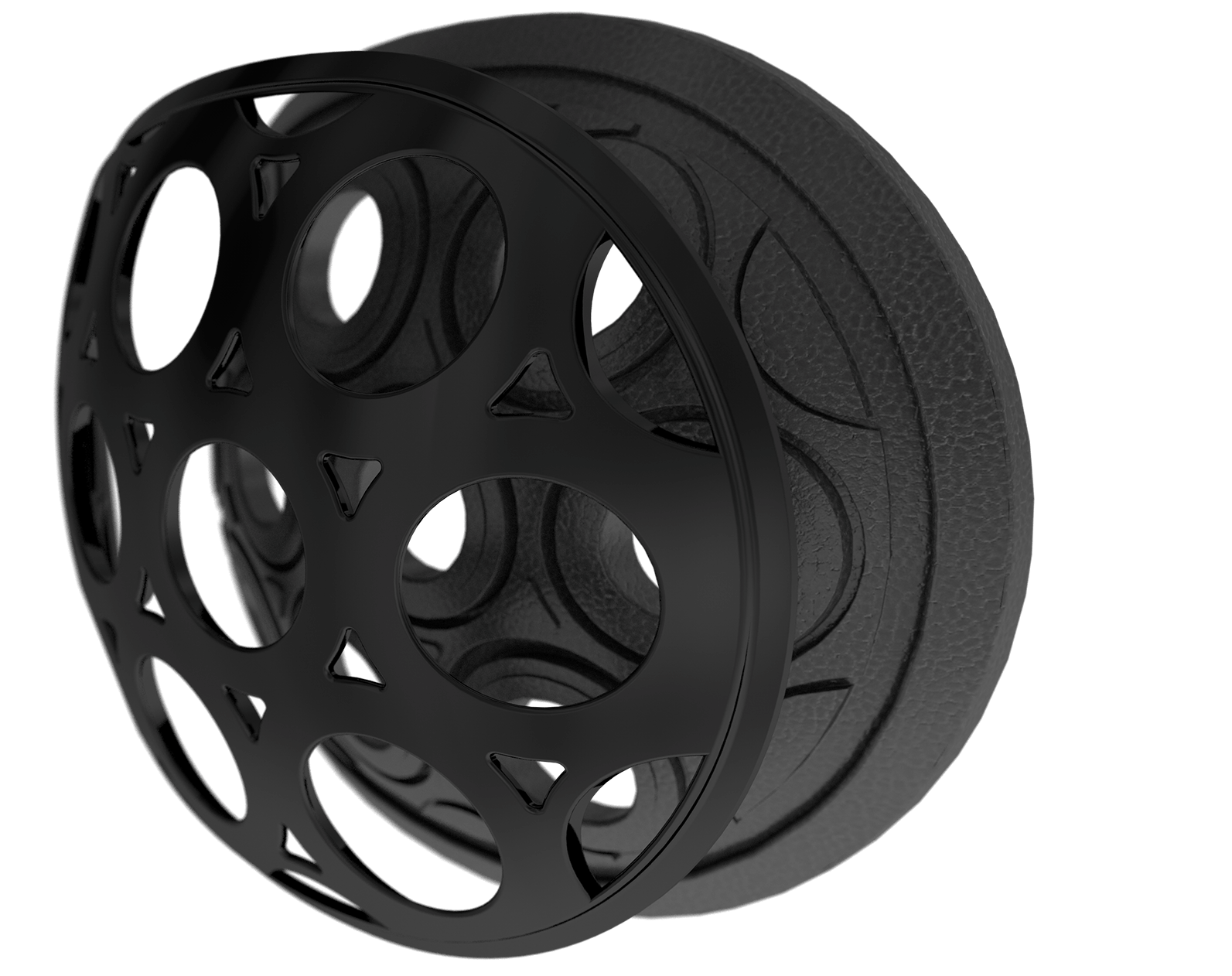

Protective

Impact energy is dispersed through the hard frame and absorbed by the base foam

Lightweight

Significantly lighter than any protective components on the market without compromising protection

Vented

Air flows through the components to cool down users and help evacuate excess heat

An essential part of the patented iBP technology is the customized protective component and its hybrid structure. Each component is built of two distinct elements combined to deliver superior properties. The HDPE injected frame is designed to be ventilated and use less material, while its structural and reinforced geometry distributes the impact. The EPP foam base, chosen for its lightness and absorption attributes, is seamlessly embedded under the frame. Combined as one, the light and vented iBP high performance components absorb and dissipate impact energy, reducing the amount of force that gets transmitted to the user’s body.

with ribbed details to add structure and

dissipate impact energy

absorption and lightness

EPP - Polymer base for superior absorption and lightness

iBP TECHNOLOGY INTEGRATION INTO ICE HOCKEY PANTS

See how customized for the ice hockey pants back, kidney, hip and thigh caps are combined in the final product design for brand TACKLA.